Resources

Find all the supporting docs you need for product selection, installation, and maintenance.

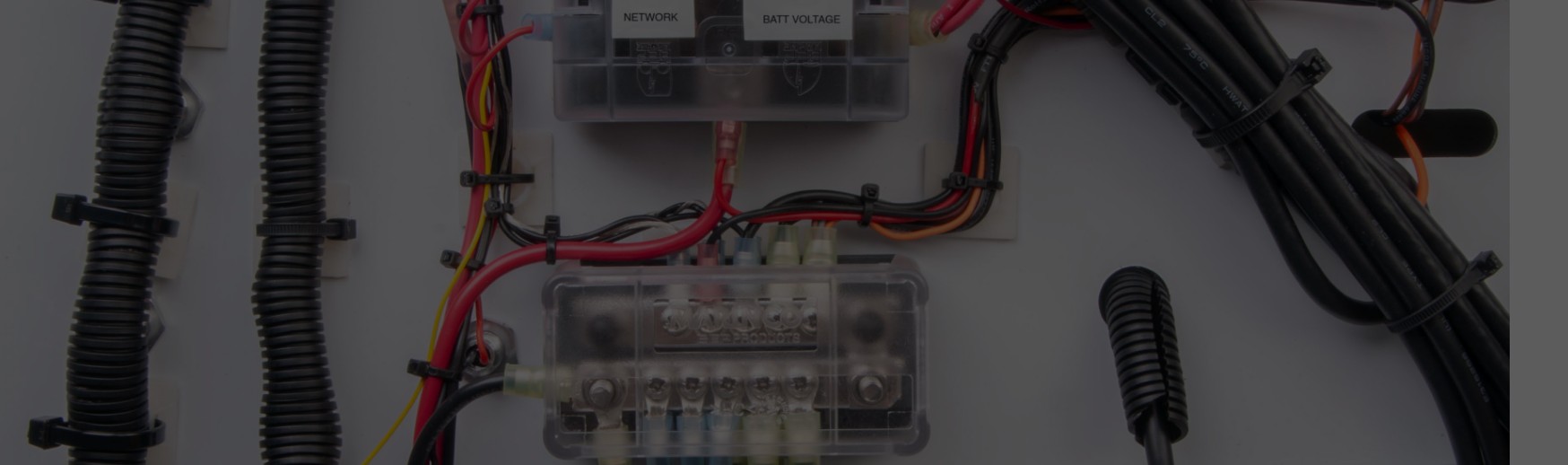

Wire & Cable

Terminals & Lugs

Tools & Testers

Wire Spec Charts

Additional Resources

Use the Circuit Wizard to select the correct wire size, circuit breaker or find the right fuse type, amperage and fuse holder.

Common marine color code compiled and adopted by most major boat manufacturers.

Answers to some commonly asked questions about ABYC standards.

Warranty Request Forms

Products

Ancor’s comprehensive product line includes everything required to complete a wiring project.

Contact Ancor

We're here to help with installation, product support, and sales.

About Ancor

Ancor’s Marine Grade® products help adventurers power their journey with confidence.

ABYC Standards

Reprinted with permission by the American Boat & Yacht Council. This is not the full text of E-11 of the ABYC standards. It is in response to some of the most commonly asked questions.

The construction of insulated cables and conductors shall conform with the requirements of: 11.16.1.2.2.1. UL 1426, Cables for Boats…”11.16.1.2.2.”

"Conductors shall be at least 16 AWG. EXCEPTIONS: 1. 18 AWG conductors may be used if included with other conductors in a sheath and do not extend more than 30 inches (760mm) outside the sheath.” 11.16.1.1.2.

"Conductors shall have a minimum rating of 600 volts.” 11.16.1.3.3. “The temperature rating of conductors and flexible cords shall be at least 140ºF (60ºC) dry.” 11.16.1.3.1.

"In engine spaces, 11.16.1.3.4.1. the insulation shall be oil resistant, and 11.16.1.3.4.2. the temperature rating shall be at least 167ºF (75ºC) dry.” 11.16.1.3.4.

"Minimum surface marking of the individual conductors and their jackets shall include: 11.16.1.1.1.1. type/style, 11.16.1.1.1.2. voltage, 11.16.1.1.1.3. wire size, and 11.16.1.1.1.4. temperature rating, dry.” 11.16.1.1.1.

"All conductors and flexible cords shall meet the flame retardant and moisture resistant requirements of UL 83,Thermoplastic-Insulated Wires and Cables.” 11.16.1.3.5.

"Conductors used for panelboard or switchboard main feeders, bilge blowers, electronic equipment, navigation lights, and other circuits where voltage drop must be kept to a minimum, shall be sized for a voltage drop not to exceed three percent”. (See Table B)

Conductors used for lighting, other than navigation lights, and other circuits where voltage drop is not critical, shall be sized for a voltage drop not to exceed 10 percent.” 11.16.1.2.7. (See Table C)

"When AC and DC conductors are run together, the AC conductors shall be sheathed, bundled, or otherwise kept separate from the DC conductors.” 11.16.4.1.5.

"Wiring shall be installed in a manner that will avoid magnetic loops in the area of the compass and magnetically sensitive devices. Direct current wires that may create magnetic fields in this area shall run in twisted pairs.” 11.16.4.2.1.

"Current-carrying conductors shall be routed as high as practicable above the bilge water level and other areas where water may accumulate. If conductors must be routed in the bilge or other areas where water may accumulate, the connections shall be watertight.”11.16.4.1.6.

"Loom used to cover conductors shall be self-extinguishing. The base product (or resin) shall be classified as V-2 or better, in accordance with UL 94, Tests For Flammability Of Plastic Materials.” 11.16.4.1.9.

"Conductors shall be supported throughout their length or shall be secured at least every 18 inches (455mm) by one of the following methods:” 11.16.4.1.10.

"By means of non-metallic clamps sized to hold the conductors firmly in place. …The material shall be resistant to oil, gasoline, and water and shall not break or crack within a temperature range of -34°C (30°F) to 121°C (250°F);” 11.16.4.1.10.1.

"By means of metal clamps lined with an insulating material resistant to the effects of oil, gasoline, and water.” 11.16.4.1.10.3.

"Terminal connectors shall be the ring or captive spade types.” 11.16.3.4.

"Twist on connectors, i.e., wire nuts, shall not be used.” 11.16.3.6.

"Ring and captive spade type terminal connectors shall be the same nominal size as the stud.” 11.16.4.1.12.

"Solder shall not be the sole means of mechanical connection in any circuit.”11.16.3.7.

"Solderless crimp on connectors shall be attached with the type of crimping tools designed for the connector used, and that will produce a connection meeting the requirements of E-11.16.3.3.” 11.16.3.8.

"The shanks of terminals shall be protected against accidental shorting by the use of insulation barriers or sleeves, except for those used in grounding systems” 11.16.3.9.

"Conductors that may be exposed to physical damage shall be protected by self-draining; loom, conduit, tape, raceways, or other equivalent protection.” 11.16.4.1.8.

ANCOR meets or exceeds all national and international standards in the marine industry, including:

Underwriters Laboratories Inc.

Cables for Boats, UL 1426

(BC-5W2), 105° C 600 volts

United States Coast Guard

CFR Title 46, Subchapter T Under 50 volts: Parts 183.05 - 45 50 volts and over: Parts 183.10 - 20

American Boat & Yacht Council

Safety for Small Craft E-8 (AC Systems), E-9 (DC Systems)

Det Nordske Veritas

High Speed Craft, Part 4, Chapter 3, Section 7

Lloyd's Register of Shipping

Part 6, Chapter 2-1, Section 7

National Fire Protection Association

Section 302

Specification Reference:

Electric Wire & Cable to be Marine Grade™, UL BC-5W2: Two conductor for 12 volts and three conductor for 120 volts as manufactured by ANCOR, Cotati, CA

Ancor is a member of:

![]()

ANCOR strongly endorses and recommends the ABYC “Safety Standards for Small Craft.” Written through the cooperative efforts of leaders from all segments of the boating industry, and interested public, these standards represent the best way to insure safety.

Wire and Cable Resources

Documentation

Terminals and Lugs Resources

Documentation

Declaration of Conformity

Tools and Testers Resources

Documentation